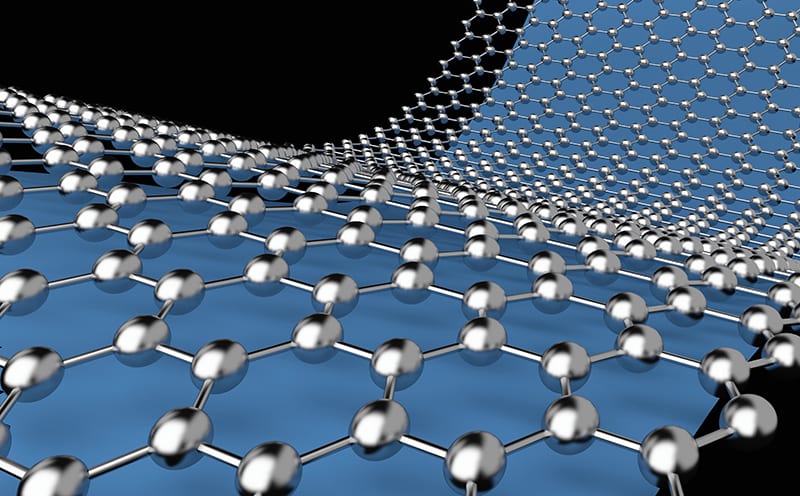

Graphene coatings are a cutting-edge development in the world of surface protection and materials science. These coatings are made using graphene—a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice. Often touted as a “wonder material,” graphene is incredibly strong, lightweight, flexible, and an excellent conductor of heat and electricity.

Graphene coatings apply this powerful material to surfaces such as metals, glass, plastics, and textiles. The goal is to enhance the properties of these materials by adding strength, resistance to corrosion and wear, conductivity, or even antibacterial functions. This technology has applications in industries ranging from automotive and aerospace to electronics and construction.

Why Graphene Coatings Matter

Graphene coatings address several real-world challenges:

Corrosion Resistance: Traditional metal surfaces corrode over time, especially when exposed to moisture and chemicals. Graphene coatings can form a nearly impermeable layer, protecting against rust and oxidation.

Thermal Management: Electronics and machines often overheat, reducing their efficiency. Due to its high thermal conductivity, graphene helps in heat dissipation.

Mechanical Strength: Surfaces treated with graphene coatings are significantly stronger and more resistant to wear and tear.

Eco-Friendly Solutions: Graphene-based coatings often require fewer chemicals and can extend the lifespan of materials, contributing to sustainability.

Industries Benefiting from Graphene Coatings

Automotive: Used for corrosion protection and reduced friction in engine parts.

Aerospace: Lightweight graphene coatings help reduce aircraft weight without compromising durability.

Electronics: Applied for heat management in smartphones, processors, and batteries.

Construction: Protects steel structures and rebar from corrosion, especially in coastal or humid regions.

Healthcare: Graphene’s antibacterial properties make it ideal for use on medical devices or hospital surfaces.

Recent Developments in Graphene Coatings (2024–2025)

The past year has seen a surge in the research and commercial application of graphene coatings:

| Date | Development | Sector |

|---|---|---|

| Jan 2024 | Rolls-Royce begins testing graphene coatings on turbine blades | Aerospace |

| Mar 2024 | Indian Institute of Technology (IIT) announces low-cost graphene coating for pipelines | Infrastructure |

| Jun 2024 | Tesla patents graphene-based paint protection system | Automotive |

| Oct 2024 | Graphene Flagship (EU program) reports success in marine corrosion trials | Marine/Shipping |

| Feb 2025 | University of Manchester develops bio-compatible graphene coatings for implants | Medical |

These innovations reflect the growing interest in replacing traditional coatings (like zinc, chrome, or PTFE) with more sustainable and high-performance alternatives.

Rules, Regulations, and Policy Landscape

As graphene enters widespread use, governments and organizations have begun addressing its safety, environmental impact, and industry standards.

International Regulations

European Union (REACH): Graphene coatings fall under the regulation of chemical substances. REACH ensures that materials are safe for humans and the environment. Manufacturers must register and test their graphene materials accordingly.

USA (EPA Oversight): The Environmental Protection Agency monitors nanomaterials, including graphene, under the Toxic Substances Control Act. Developers must submit data on health impacts and disposal methods.

India (BIS & DST): India is formulating standards for advanced coatings, with the Bureau of Indian Standards (BIS) and Department of Science and Technology (DST) involved in drafting safety protocols for graphene-related products.

Government Programs

Graphene Flagship (EU): A €1 billion initiative to bring graphene innovation to market, supporting projects in coatings and beyond.

National Graphene Institute (UK): Facilitates partnerships between academia and industry, especially in the area of protective coatings.

National Mission on Quantum Technologies and Applications (India): Although primarily focused on quantum research, it indirectly supports materials science, including graphene.

Tools and Resources

For professionals, researchers, or curious individuals interested in graphene coatings, several tools and platforms provide valuable assistance:

Websites and Databases

The Graphene Council – Offers white papers, webinars, and industry reports.

Nanowerk – Provides updates on nanomaterials, including graphene coatings.

ScienceDirect & PubMed – Useful for academic research on graphene’s chemical and physical behaviors.

Calculators and Simulation Tools

COMSOL Multiphysics: Advanced simulation software to model graphene-coated systems for thermal, structural, or electrical analysis.

MATLAB Nanotoolboxes: Useful for designing and simulating graphene behavior under stress or heat.

Industry Associations

European Coatings Journal – Covers emerging technologies, including graphene in paints and industrial coatings.

American Coatings Association (ACA) – Provides educational materials, policy updates, and webinars.

Templates and Standards

ISO/TS 80004-13:2017 – Defines terminology and standards for graphene materials.

Coating Lifecycle Assessment Tools – Used in construction and automotive industries to assess the environmental impact of using graphene coatings.

Frequently Asked Questions (FAQs)

What is the difference between graphene oxide and pure graphene in coatings?

Graphene oxide (GO) contains oxygen groups that make it easier to disperse in water-based solutions, commonly used in coatings. Pure graphene, while stronger and more conductive, is harder to apply due to poor solubility. Many commercial coatings use a blend or reduced graphene oxide (rGO) to balance performance and processability.

Are graphene coatings safe for human health?

Current studies suggest that graphene coatings are generally safe when used in solid or bonded forms. However, airborne graphene particles or prolonged skin contact during manufacturing may pose risks. Regulatory bodies like the EPA and EU REACH are investigating long-term impacts.

Can graphene coatings be applied to consumer products?

Yes. Graphene coatings are increasingly found in electronics, sports equipment (like tennis racquets), car paints, and even textiles. Some high-end smartphone screen protectors also use graphene for durability and clarity.

How are graphene coatings applied?

Common application methods include:

Spray coating

Dip coating

Spin coating

Chemical Vapor Deposition (CVD) for industrial applications

The method depends on the substrate material and the intended purpose.

Are graphene coatings expensive?

Costs are currently higher than traditional coatings, due to the complexity of production and raw material synthesis. However, prices are expected to decrease as mass manufacturing scales up and innovations in graphene production (like from biomass or waste) are commercialized.

Final Thoughts

Graphene coatings represent a remarkable advancement in surface protection technology. From improving durability and thermal performance to reducing environmental impact, they hold promise across many sectors. While still evolving, regulatory oversight and research collaboration are making graphene coatings more accessible and safer.

As developments continue into 2025 and beyond, graphene’s potential in reshaping industrial coatings and everyday products becomes more tangible. Staying informed through credible sources, regulations, and practical tools can help individuals and organizations leverage this innovation responsibly and effectively.